CAM Service

From CAD to Code – optimized toolpaths for efficient, collision-free machining.

“The bridge between imagination and precision.”

Our Programming Office converts CAD to machine-ready code with zero guesswork.

How we do it

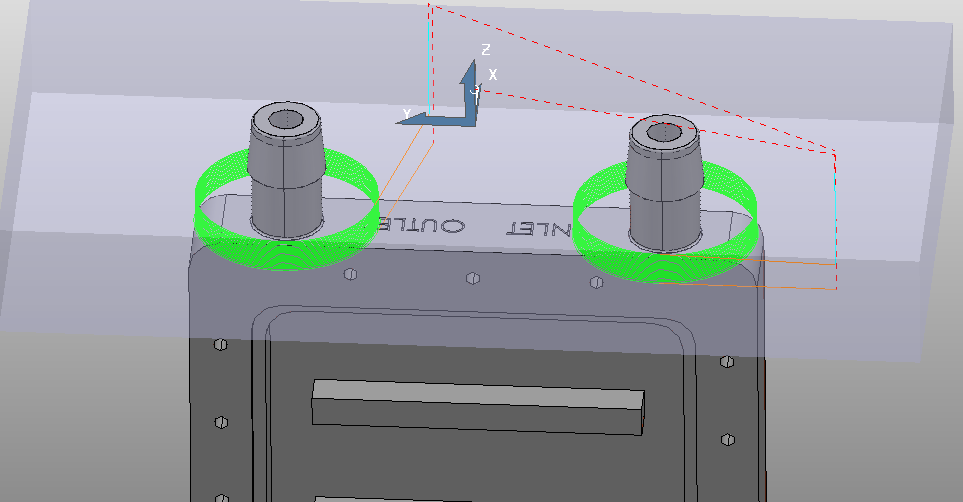

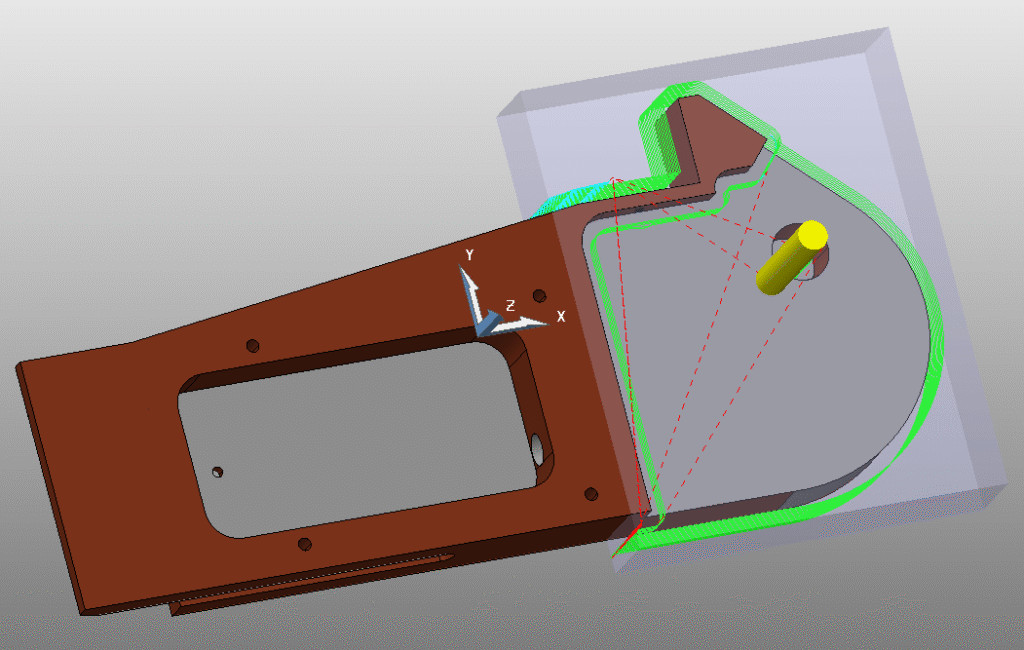

Toolpathing: Complex 3D/5-axis strategies in PowerMill (adaptive clearing, rest machining, scallop/constant-Z finishing, swarf for walls).

Post-Processing Verified posts per machine control; standardized work offsets, tool numbering, and coolant commands.

Virtual Proofing Full simulation for gouge/collision checks, holder clearances, over-travel, and cycle-time estimation.

Setup Packs Fixture drawings, tool lists, cutting data, probing cycles, and quality checkpoints so operators run first-time-right.

Outcome Safe, efficient NC programs that protect machines, tools, and deadlines.