Quality Control & Inspection Service

Ensuring product accuracy and maintaining high performance standards.

“Quality is never an accident; it’s intelligent effort.”

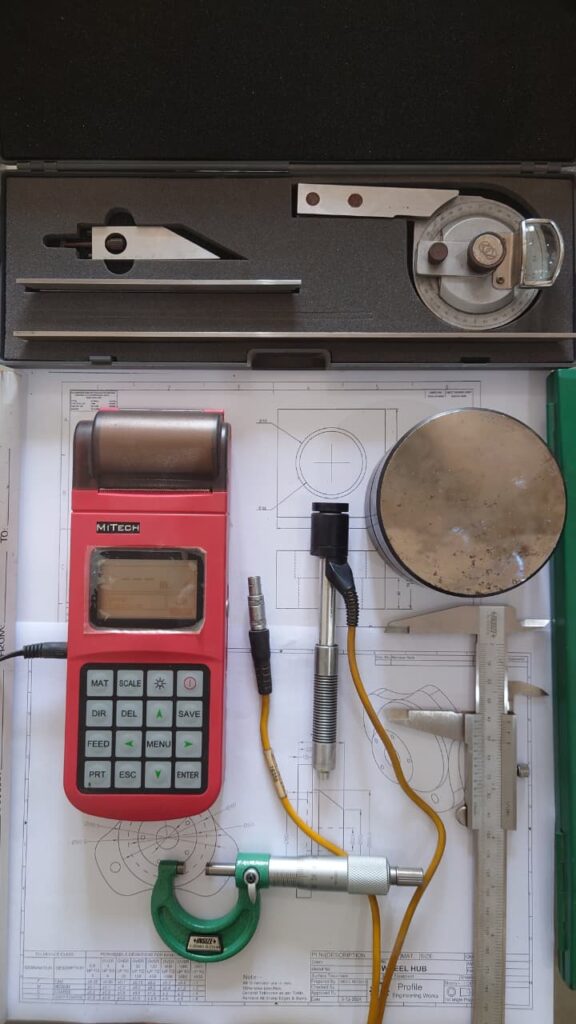

Metrology & instruments

Dimensional Vernier calipers ranges from 0–1000 mm, micrometers ranges from 0–300 mm, bore gauges, slip & snap gauges, plug gauges, height gauges, surface plates (both metallic and ceramic), angle plates.

Hardness Portable and bench testers for on-machine checks and final verification.

CMM Coordinate Measuring Machine (under installation) for high-accuracy 3D inspection and automated reports.

Process & governance

Inspection Plan IQC (incoming), IPQC (in-process), FQC (final), OQC (pre-dispatch).

MSA & Calibration Gage R&R studies on key checks; scheduled calibration with traceable records; controlled environment for metrology.

Documentation FAIR/FAI, material certificates, and heat-treatment records available on request.

Outcome Measured conformity, traceability, and confidence, part after part, lot after lot.